JSA SERVICE ANNOUNCE ITS EXCLUSIVE UK REPRESENTATION OF MICROGUARD1® 3500, ADSIL’S NEW MARKET-LEADING HVAC/R COATING

October 26, 2021

Introducing Microguard1® 3500, an advanced inorganic formula that protects against corrosion, heat, UV light, pollution and chemical assault that other coatings cannot.

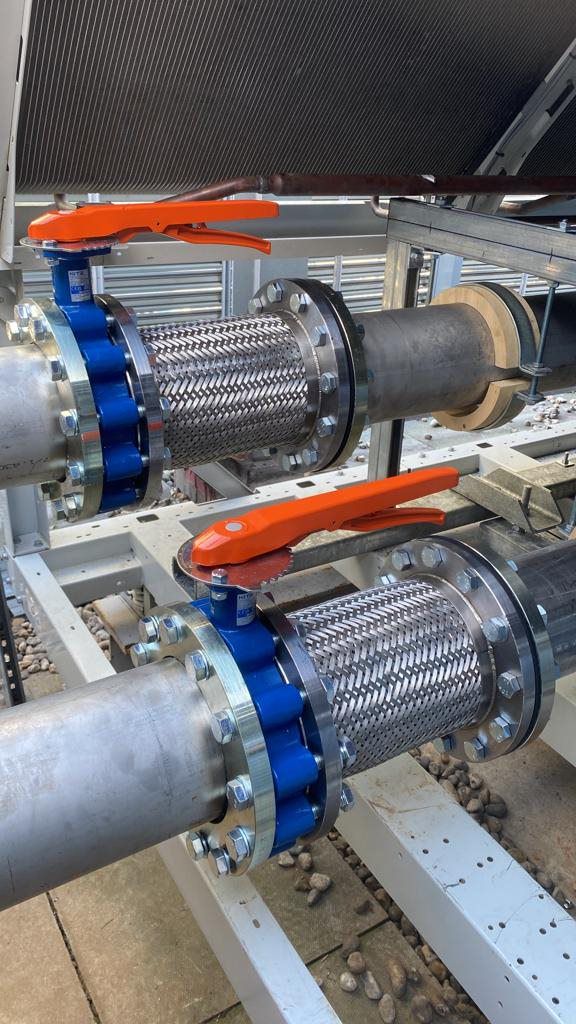

Air Conditioning and Chiller Specialists JSA Service are proud to announce they are currently the only certified installers of MicroGuard1® 3500 (MG1-3500) in the UK. Produced in Florida, USA and released after years of research in May 2020, MG1-3500 is an advanced, one-component, siloxane-based HVAC/R coating that is easy to use, is a LOW VOC product, and outperforms similar commodities. Designed for use on heating and air conditioning equipment; coils, fins, tubes, fans and even cabinets, MG1-3500 is among the most advanced protective coating available. Proven to positively arrest corrosion, protect against chemical and environmental assault, extend the life of equipment, save energy and mitigate microbial growth, providing sustainable results with a verifiable ROI.

The new MG1-3500 also has an impressive performance including surpassing 10,000 hours in the ASTM B117 Salt Fog test, proving its superiority against competitors within the market.

Allan Wilkinson, JSA Service Managing Director states:

“We’re excited to introduce the next generation of HVAC coatings to our customers and the UK market. Our motto is to provide a service we maintain’ and by offering MG1-3500’s advanced inorganic formula, we believe we can reduce maintenance and energy costs and therefore outperform our competitors!”

MG1-3500 is a cross link cured, glass-like film that chemically bonds to non-ferrous metal ensuring maximum adhesion and protection in the harshest environments. At 6-8 microns thick, the coating preserves HVAC/R system’s original performance without affecting heat transfer or laminar air flow.

View our digital MicroGuard1® 3500 brochure HERE

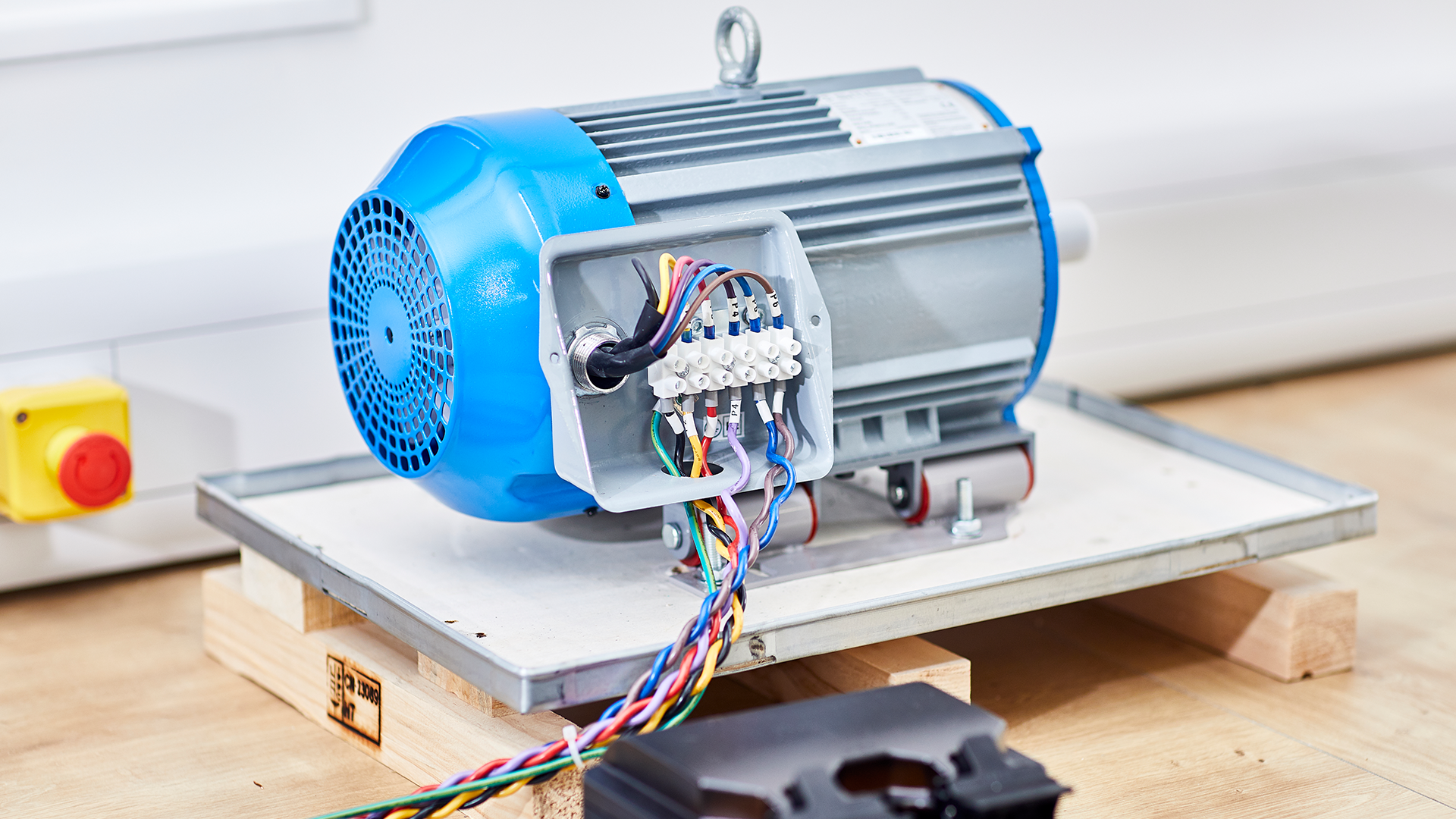

A Full Turnkey HVAC (Heating, Ventilation, and Air Conditioning) Project offers several significant benefits for commercial clients. Here are some of the key advantages: Single-Point Responsibility: With a full turnkey project, you have a single point of contact responsible for the entire project, from design to installation and ongoing maintenance. This simplifies project management, reduces communication challenges, and streamlines accountability. Cost Efficiency: Turnkey projects often result in cost savings due to economies of scale. The project manager can negotiate better deals with suppliers, optimize resource allocation, and minimize costly delays. Faster Project Completion: The streamlined process of a turnkey project typically leads to quicker project completion. Since the project team is integrated and works cohesively, there are fewer delays and bottlenecks. Quality Assurance: The project manager oversees all aspects of the project, ensuring that quality standards are met at every stage. This reduces the risk of defects or subpar workmanship. Reduced Risk: By entrusting the project to a single experienced contractor, clients can minimize their exposure to risk. The contractor assumes responsibility for managing unexpected issues, such as design changes or unforeseen construction challenges. Customised Solutions: A full turnkey project allows for tailored HVAC solutions that meet the specific needs of the client. The design, equipment selection, and installation are all customized to ensure optimal performance and energy efficiency. Simplified Communication: Clients don't have to coordinate between multiple contractors, which can be complex and time-consuming. Instead, they can communicate directly with the project manager, ensuring clarity and efficiency. Energy Efficiency: HVAC experts can design and install systems that are highly energy-efficient, resulting in lower long-term operating costs and a reduced environmental footprint. Compliance and Regulations: The project manager is responsible for ensuring that all necessary permits and regulations are adhered to, reducing the risk of non-compliance issues. Maintenance and Support: Many full turnkey HVAC projects include ongoing maintenance and support contracts. This ensures that the HVAC system continues to operate efficiently over its lifespan, reducing downtime and repair costs. Peace of Mind: Clients can have peace of mind knowing that their HVAC project is in the hands of professionals who have the expertise and experience to deliver a successful outcome. In summary, a Full Turnkey HVAC Project offers convenience, cost-efficiency, and quality assurance. It simplifies the process for clients while providing them with customised, energy-efficient HVAC solutions that meet their specific needs and compliance requirements. It's a comprehensive approach that ensures a successful and hassle-free HVAC installation and operation.

With the UK energy crisis in full swing, building and facility managers must start making changes to improve energy efficiency on building HVAC systems to significantly reduce power bills. The combination of heating, ventilation and cooling often consumers the most energy for a commercial building, and according to the Department of Energy, HVAC systems use about 35% of a building’s energy on average.